(Shape Memory Polymers and Their Applications)

本书为《软物质前沿科学丛书》之一。

(1)

91年诺奖得主德热纳其演讲主题为—“软物质”,可称为软凝聚态物质,含液晶、聚合物、双亲分子、生物膜、胶体、黏胶及颗粒物质。

可参看 de Gennes

软物质处于固体和理想流体之间的复杂凝聚态物质,主要共同点是其基本单元之间的相互作用弱(室温热量级),因而易受温度影响,熵效应显著,且易形成有序结构。

因此具有显著热波动、多个亚稳态、介观尺度自组装结构、熵驱动的有序无序相变、宏观的灵活性等特征。

简言之,“小刺激,大反应”和强非线性特征。更多由介观多级自组装结构决定。

形状记忆聚合物(shape memory polymers)具有刺激-响应性,表现出感知与驱动为一体。在自愈合,可重构,大应变,多刺激及双向可逆,特别是4D打印有前景。

Shape-memory polymers are an emerging class of polymers with applications spanning varios areas of everyday life. Such applications can be found in, for example, smart fabrics, heatshrinkable tubes for electronics or films for packaging, self-deployable sun sails in spacecraft, self-disassembling mobile phones, intelligent medical devices, or implants for minimally invasive surgery. These examples cover only a small number of the possible applications of shape-memory technology, which shows potential in numerous other applications. In this review, the fundamental aspects of the shape-memory effect are presented.

(2)

1951年,就发现了交联聚乙烯的热致形状性能。

SMA(shape memory alloy)在专利里,最先出现在1963年,是美国海军武器研究所的一种镍钛合金专利。

NASA,CDF Chimie,Mitsubishi, Zeon等从80年代,开始研究SMP。

形状记忆聚合物必须有一定的形状固定率与形状回复率。

形状记忆(shape memory)是聚合物的能力而不是性质,因此通过结构设计或与其他材料复配,很多聚合物可显示出形状记忆性能。

通过对聚合物硬段(化学交联点、链段物理缠结、聚合物结晶、分子间相互作用),与软段(链段的相转变、可逆化学键合)的合理调控,材料能够固定临时形状,并在感知外界刺激作用后发生形状变化,回复到初始的永久形变。

热致SMP(shape memory polymer)是研究其它类型SMP的基础。

SMP特有的刺激—响应由其特有的微观结构决定。

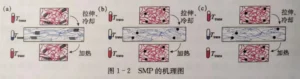

热致SMP由可逆相与固定相组成,固定相起到保持原始形状的作用,由材料的物理或化学交联点承担;可逆相起到保持临时形状的作用,由链段的熔融—结晶或无定形—玻璃化过程承担。

加热达到可逆相的熔点或玻璃化转变温度时,可逆相链段能够自由运动,在此时能够赋形,接着,利用降温,使分子链结晶或玻璃化来固定可逆相,而获得临时形状。

再次升温,超过可逆相的熔点或玻璃化转变温度时,收到熵变驱动,链段再次自由运动趋于回复到自由状态,回到原始形状。

(可以试想泡在口香糖里的金属弹簧,低温固化,再融化)

上图a,b,c 分别代表物理交联半结晶热塑、化学交联半结晶和化学交联玻璃态热固。从赋形到回复的机理。

Ttrans = thermal transition temperature related to the switching phase

The shape-memory effect is not an intrinsic property, meaning that polymers do not display this effect by themselves. Shape memory results from a combination of polymer morphology and specific processing and can be understood as a polymer functionalization. By conventional processing, e.g. extruding or injection molding, the polymer is formed into its initial, permanent shape B. Afterwards, in a process called programming, the polymer sample is deformed and fixed into the temporary shape A. Upon application of an external stimulus, the polymer recovers its initial permanent shape B. This cycle of programming and recovery can be repeated several times, with different temporary shapes in subsequent cycles. In comparison with metallic shape-memory alloys, this cycle of programming and recovery can take place in a much shorter time interval and polymers allow a much higher deformation rate between shapes A and B.

Shape-memory polymers are elastic polymer networks that are equipped with suitable stimuli-sensitive switches. The polymer network consists of molecular switches and netpoints . The netpoints determine the permanent shape of the polymer network and can be of a chemical (covalent bonds) or physical (intermolecular interactions) nature. Physical cross-linking is obtained in a polymer whose morphology consists of at least two segregated domains, as found for example in block copolymers. Here, domains related to the highest thermal transition temperature (Tperm) act as netpoints (a hard segment), while chain segments in domains with the second highest thermal transition Ttrans act as molecular switches (a switching segment). If the working temperature is higher than Ttrans, then the switching domains are flexible, resulting in an entropic elastic behavior of the polymer network above Ttrans. If the sample has been previously deformed by application of an external stress, it snaps back into its initial shape once the external stress is released. The molecular mechanism of the shape-memory effect is illustrated for the thermally induced shape-memory effect in. The shape-memory polymer network consists of covalent netpoints and switching segments based on a physical interaction.

为了让SMP能用,提高机械性能等,常采用无机纳米粒子或纤维填充。

形状记忆性能常采用弯曲实验和拉伸实验来表征,来计算得到暂时、永久、残余形变。

(SMP的应用无处不在,你察觉到了吗?)